helical end mills feeds and speeds

Calculations use the desired tool diameter number of teeth cutting speed and cutting feed which should be. SFM 08 X Highest Speed Range.

Had my Ingersoll rep out here one day Ingersoll supplies almost all my carbide insert tooling and I asked him about the Ingersoll carbide end mills.

. Helicals fully stocked offering of High Feed End Mills is designed for outstanding performance and maximum feed rates in aluminum and non-ferrous materials. SFM and Feed For AD between 025 to 05 of Tool Dia. Take Advantage of Saving Time Money with Chance Helical Products.

Hanita used to be my favorite but Helical displaced them a few years back. End Mill Speeds And Feeds - TiN Coated Carbide. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill.

High Helix Carbide End Mill At Rs 3000 Unit Solid Carbide End Mills Id 20478637012 Series 6774 Inch Rf100 Speed 4 Fl Extra Length End Mill Guhring 4 6 Flute High Feed End Mills Epic Tool. Feeds and Speeds Information for VoluMill. Generate specialized machining parameters by pairing your end mill with your exact tool path material and machine setup.

Since not every company has the RPM or need for high Metal Removal Rates MRR. Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure. Access the app anywhere you need it even offline making it easy to.

Check out the speeds and feeds chart. - Can also be made with CBN Flutes CBN End Mills. I-Smart Replaceable Head System.

Viper DVH Speeds Feeds. - 00 -70 7 Helix. I would use a 58 WhisperKut from Dura-Mill.

- Dimension tolerance. Want to know what feeds and speeds others are using. Variable Helix End Mills for Aluminum Alloys - Chipbreaker Roughers - Square The unique geometry of this solid carbide 3 flute Harvey Tool features a variable pitch design and chipbreaker geometry for reduced chatter and harmonics increased MRR and improved chip management while machining aluminum.

Use the light roughing as described at the bottom of the chart. Dura-Mills WhisperKut Speed and Feed High Performance End. Our Viper DVH series end mills are for both roughing and finishing.

Helical PCD End Mills. PCD End Mill is a superior cutting tools capable of side cutting and center cutting with high feeds and speeds. SFM 08 Lowest Range Value.

MULTI PURPOSE PM60-ONLY ONE. Machining Advisor Pro calculates optimal running parameters based on material type end mill features machine set-up tool path and other factors to help users get the most outof Helical end mills. For AD equal and above Tool Dia.

Using MasterCam dynamic milling and whisperkuts end mills. Nowhere in the line do you program a ramp angle however you do enter a z movement. Kennametal Helical Milling Interpolation Calculator For End Milling Application These calculations are based upon theoretical values and are only intended for planning purposes.

Download Standard Speeds Feeds. Feed should be 05 X Suggested Value. Speeds and feeds speeds and feeds for boring tools material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15.

Mild - 1018 2-3 Carbon 420 0006016mm 0011028mm 0017043mm 002051mm. When calculating spindle speed I recommend using 70 of normal slotting cutting speed for this material and the feedrate should be divided by the number the End Mills flutes. We cut slots all day long in 4140.

Feed at Suggested Value. They should also shorten your run time too. Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure.

Request a Quote Now. Ad Our Wide Offering Of End Mills Encompasses All Types Of Applications. You can also watch videos of machining tests that use those parameters.

CBN 2 FLUTE 30 DEGREE HELIX BALL END MILL. Click on the buttons below to get a printable table of parameters for the material listed. What Im attempting to do is optimize my feeds and speeds to gain better control of accuracy and finish.

Speeds SFM should be reduced approximately 20 of lowest range value Above recommendations are to be used when axial depth-of-cut does not exceed 1 12. - Can be made with 2 or 3 or 4 Flutes. - With or Without coolant.

For Lighter Radial Depths-of-Cut. Ideally the depth of your plunge should not exceed one diameter of the end mill. Ad Foundation Technologies Is the Industrys Leader in Trust Reliability.

Feeds - IPT inchestooth and MMPT mmtooth Material. I-Xmill Indexable Ball Nose System. Higher range of recommended surface speeds should be used For Greater Radial Depths-of-Cut.

Its reduced neck geometry provides maximum strength in long reach and deep pocketing applications while its end profile provides optimal tool engagement and reduced cutting forces. If you think about my hole mentioned in the first post a 375 cutter creating a 75 hole the ramp angle is actually going to be 90 degrees on the inside. Lower range of recommended surface speeds should be used For Slotting Applications.

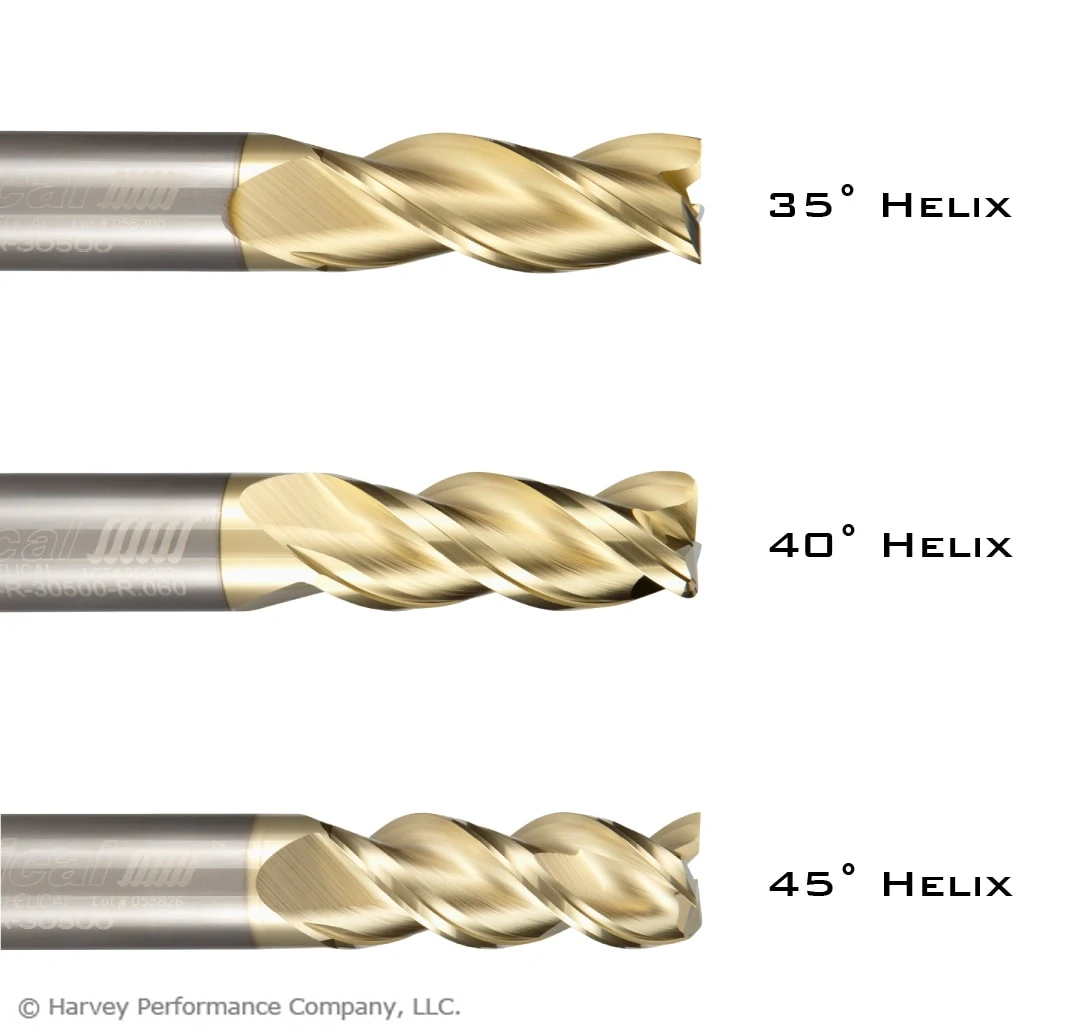

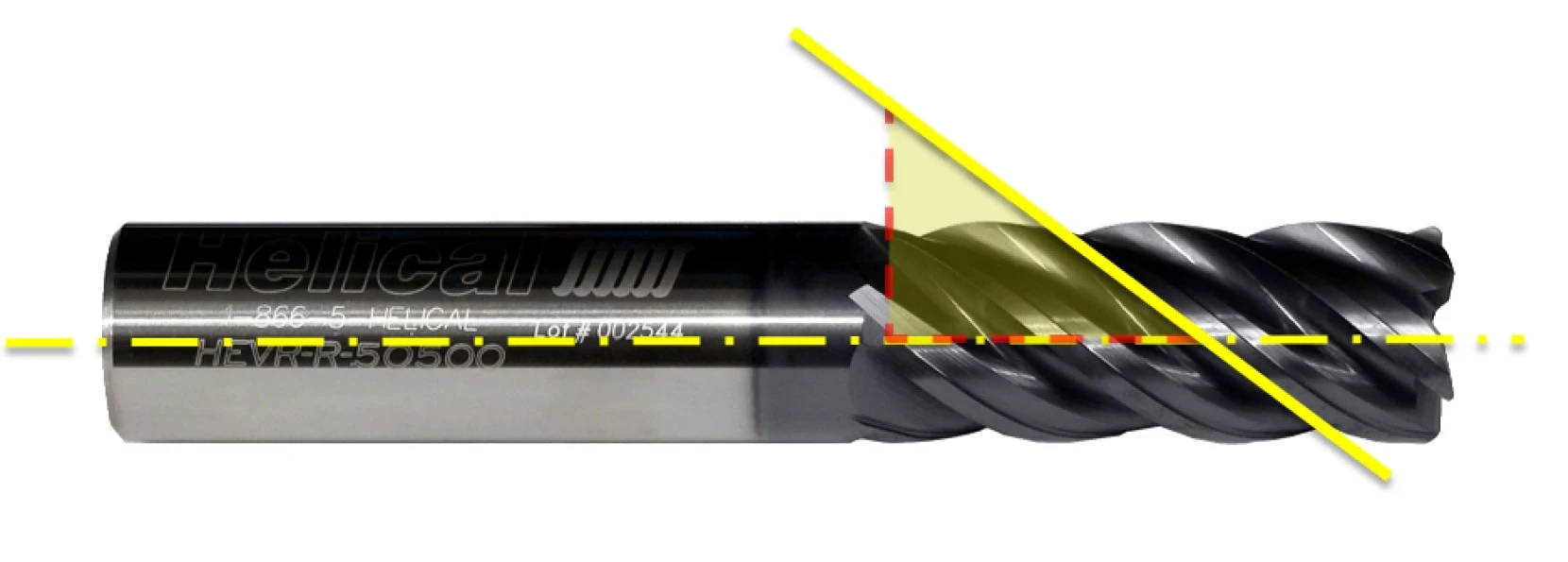

HSMAdvisor by default suggests plunging Speed and Feed according to these guidelines. 45 Degree Variable Helix Primarily for high-speed machining of aluminum plastics and other non-ferrous materials including brass and bronze alloys. Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length.

SMM SFM X 3048. PARAMETERS ON THE FLY. CUSTOMIZABLE SPEEDS FEEDS.

Helical makes the best endmills considering price and what they do for you.

Helix Diameter Archives Harvey Performance Company

End Mill An Overview Sciencedirect Topics

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

Helix Diameter Archives Harvey Performance Company

Gmg12 6 Flute 12mm V7 Plus Carbide End Mill Cutwel Milling Tools Cutwel Ltd

End Mill Selection Guide By Mekanika Wikifactory

End Mill Helix Angle Selection Blogs Www Cnctimes Com

Global Cutting Tools End Mills Cutting Tools Metalworking Extreme3

16mm Dia 2 0mm Corner Radius 4 Flute Variable Helix Angle High Performance Carbide End Mill Associated Production Tools

Series 6774 Inch Rf100 Speed 4 Fl Extra Length End Mill Guhring

3 Flute Carbide End Mill For Aluminium 4mm Diameter 45 Helix Associated Production Tools

5 Things To Know About Helical S High Feed End Mills In The Loupe

Stability Lobe Diagrams For Milling System With Different End Mills A Download Scientific Diagram

An In Depth Look At Helical S Tplus Coating For End Mills End Mill Hardened Steel Multi Layering

Global Cutting Tools End Mills Cutting Tools Metalworking Vortex5

1575 4mm 3 Flute Carbide Ball End Mill Se 38 Deg Helix 551 Loc Maritool

Specification Variable Helix End Mill

Conical Tapered End Mills Cutting Tools Metalworking Helical Angle

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool